E-posformaatfout

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nuus

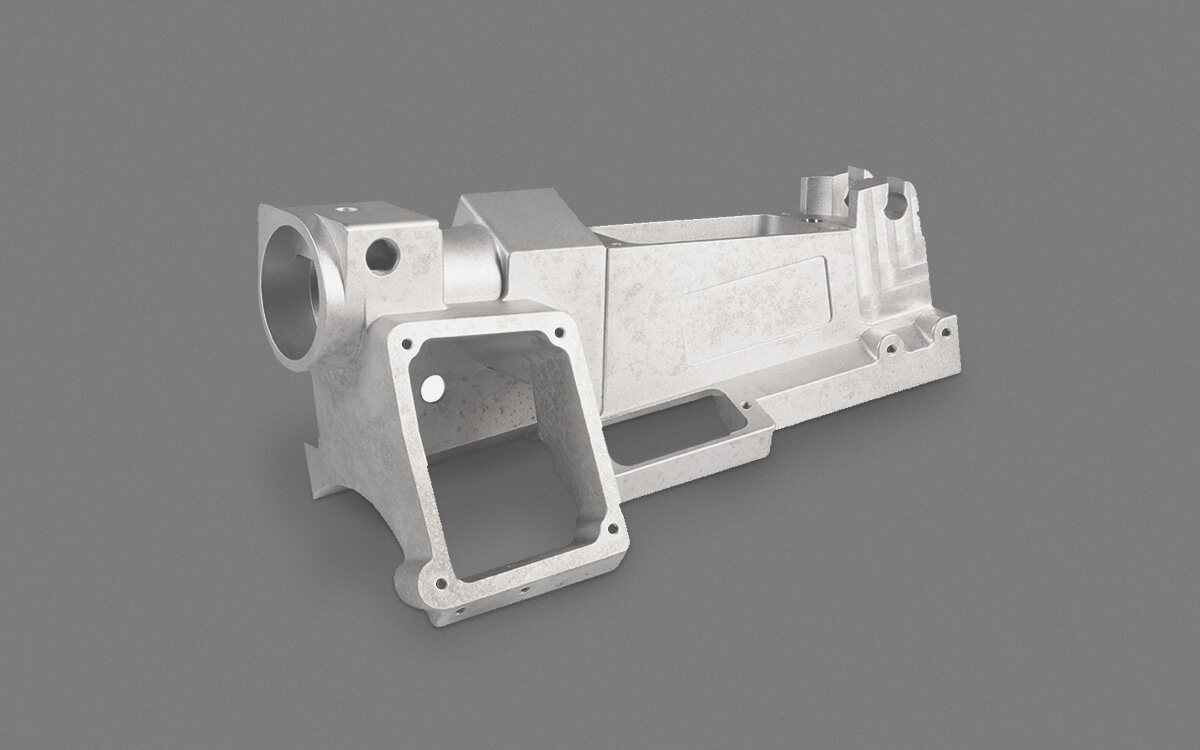

aluminium alloy die casting parts factory, manufacturer

Aluminum alloy dies casting parts are common die casting parts. The aluminum and aluminum alloy heated to a liquid state is cast to the material mouth with a die casting machine, and the parts are manufactured by the die casting machine. The aluminum alloy dies casting parts after die casting can produce various complex shapes, and have high precision and finish. It can not only save power and metal materials but also save bad labor costs.

Today, as a professional aluminum die casting parts manufacturer, we will discuss the selection of parting surfaces of aluminum alloy die casting parts.

What is the parting surface?

The contact surface between moving die and fixed die casting die is usually called the parting surface. The parting surface is determined by the parting line of the die casting. The joint surface perpendicular to the direction of die locking force is the basic parting surface.

Generally speaking, the die casting die has only one parting surface. Due to the complexity of castings, there are sometimes more than two auxiliary parting surfaces.

Type of parting surface

According to the shape of the parting surface, the parting surface of the die casting die can be divided into straight type, inclined type, stepped type, and arc type. The straight parting surface has the advantages of simple structure, convenient manufacture, and wide application. For the stepped parting surface, the gating system is generally set on a one-step surface and the overflow system is set on the other step surface to facilitate the filling and discharging of liquid metal.

Many factors need to be considered in determining the parting surface. Therefore, in the selection of parting surface, in addition to the structural characteristics of aluminum alloy die casting parts and the layout of the gating system. The processing technology, assembly technology, and molding conditions of aluminum alloy die casting die should be comprehensively considered and determined.

Determination principle of parting surface

- During mold opening, the casting must remain in the moving mold and be easy to take out from the mold cavity.

- Parts with different axial degrees and high dimensional accuracy requirements shall be set in the same half die as far as possible.

- The parting surface is generally not set on the surface with high-quality requirements.

- The setting of the parting surface shall be conducive to the setting of the gating system, eliminate burrs, flash, gate, etc., and be conducive to coating.

- The setting of the parting surface shall simplify the structure of aluminum alloy die casting parts as much as possible, and fully consider the casting performance of the alloy.

We are a leading and professional aluminum die casting parts factory, our company supplies cast iron, die casting, aluminum castings, industrial cast aluminum, cast aluminum crafts, Precision Casting Parts, etc., and provides cast aluminum processing and cast iron processing.

And we want to be your long-term partner, any interested, welcome to contact us.

Our company supplies cast iron, die casting, aluminum castings, industrial cast aluminum, cast aluminum crafts, Precision Casting Parts, etc., and provides cast aluminum processing and cast iron processing. The company has exquisite technology, complete production, and testing equipment, and a strong technical force. It is your reliable partner. Our company sells well all over the country with low price and perfect service and meets the requirements of every customer to a great extent.