E-posformaatfout

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nuus

high pressure die casting machine price,pressure die casting machine parts,high pressure die casting materials

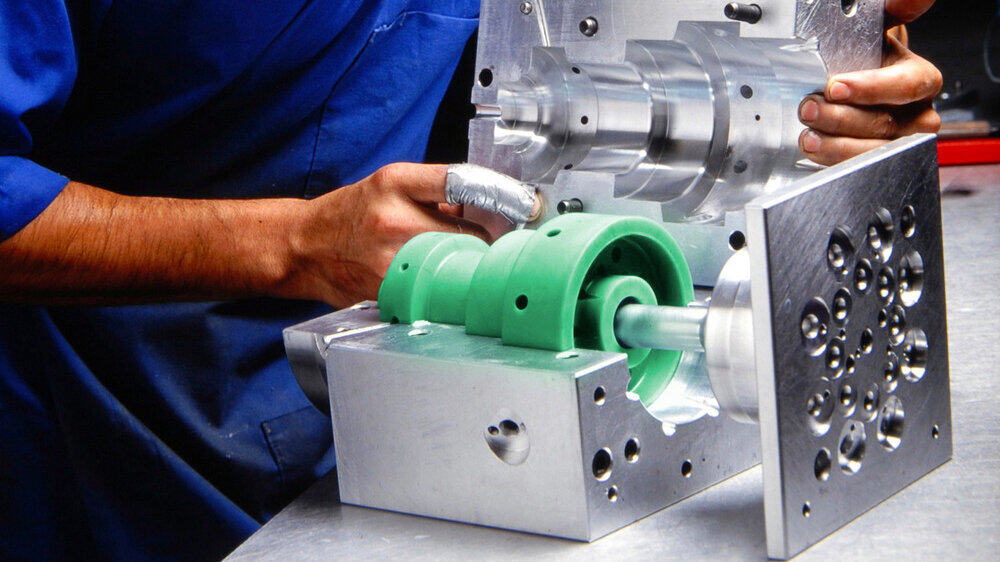

High pressure die casting is a process of filling liquid or semi-solid metals or alloys, or liquid metals or alloys containing reinforcing phases, into the cavity of a die-casting mold at a high speed under high pressure, and making the metal or alloy under pressure A casting method for solidification to form a casting. In general, the common high pressure die casting materials are aluminium alloy and zinc alloy, etc.

The pressure commonly used in die casting is 4-500MPa, and the metal filling speed is 0.5-120m/s. Therefore, the filling time of the molten metal is very short, and the cavity can be filled in about 0.01-0.2 seconds (depending on the size of the casting). Therefore, high pressure and high speed are the fundamental differences between die casting parts and other casting methods.

Steps of high pressure die casting

High pressure die casting is mainly divided into 4 steps: mold preparation, filling, injection and falling sand, which are also the basis of various improved die casting processes.

- Lubricant is sprayed into the mold cavity during the preparation process. In addition to helping control the temperature of the mold, the lubricant can also help the casting release.

- The mold can then be closed and the molten metal injected into the mold at high pressure, which ranges from about 10 to 175 MPa.

- When the molten metal is filled, the pressure is maintained until the casting solidifies, and the push rod pushes out all of the casting. Since there may be multiple cavities within a mold, multiple castings may be produced during each casting.

- The process of falling sand requires separation of residues, including mold openings, runners, gates, and flash. This process is usually done by squeezing the casting through a special trim die. Other methods of falling sand include sawing and sanding. If the gate is fragile, you can directly beat the casting, which can save manpower. Excess mold openings can be reused after melting. The usual yield is about 67%.

Precautions for pressure die casting machine parts

High-pressure injection causes the mold to be filled very quickly, so that molten metal fills the entire mold before any part solidifies. In this way, surface discontinuities can be avoided even in thin-walled sections that are difficult to fill. However, this also leads to air entrapment, as it is difficult for air to escape when filling the mold quickly.

This problem can be reduced by placing vents on the parting line, but even very precise processes can leave porosity in the center of the casting. Most die castings can complete some structures that cannot be done by casting through secondary processing, such as drilling and polishing.

After the fallout is complete, defects can be inspected. The most common defects include stagnation (underfill) and cold scars. These defects can be caused by insufficient mold or molten metal temperature, metal contamination, too few vents, too much lubricant, etc. Other defects include porosity, shrinkage, thermal cracking, and flow marks. Flow marks are marks left on the casting surface by gate defects, sharp corners, or excess lubricant.

Why add lubricants during preparation?

Water-based lubricants, known as emulsions, are the most commonly used type of lubricant for health, environmental, and safety reasons. Unlike solvent-based lubricants, it does not leave by-products in castings if the minerals in the water are properly removed by a process. If the water is not treated properly, minerals in the water can cause surface defects and discontinuities in the casting.

There are four main types of water-based lubricants: water-oil, oil-water, semi-synthetic, and synthetic.

Oil-in-water lubricants are the best, because when lubricants are used, the water cools the surface of the mold by evaporation while depositing the oil, which can aid in mold release. Typically, the ratio of such lubricants is 30 parts water to 1 part oil. In extreme cases, this ratio can reach 100:1.

Historically, solvent-based lubricants commonly used include diesel and gasoline. They are good for casting ejection, however small explosions occur during each die casting process, which results in a build-up of carbon on the cavity walls. Solvent-based lubricants are more uniform than water-based lubricants.

In the end

The above are the common steps for preparing high pressure die casting. If you want to order, please feel free to consult us, we will give you a competitive high pressure die casting machine price.